Foxconn Technology Group’s recent recall of Chinese staff to its operations in China is raising questions about the company’s ambitious plans to ramp up iPhone production in India. As Apple seeks to diversify its manufacturing footprint outside China, the move underscores the operational and logistical challenges that come with relocating skilled labor in the midst of geopolitical tension and ongoing supply chain pressures.

The Recall and Its Context

Foxconn, Apple’s primary contract manufacturer, reportedly requested that a number of Chinese engineers and technicians return to its Chinese plants to address operational bottlenecks. Sources suggest the recall is intended to stabilize production and meet surging domestic demand in China, which remains Apple’s largest single-country market.

The decision comes at a sensitive moment, as Apple has invested heavily in its Indian operations. Facilities in Tamil Nadu and Karnataka are being scaled to produce millions of iPhones annually, with the goal of gradually replacing China’s dominance in Apple’s supply chain.

Implications for Apple’s India Strategy

The temporary redirection of Chinese staff to China could slow the ramp-up of Indian production, highlighting the dependence on experienced labor for complex electronics assembly. While India offers lower labor costs and incentives for high-tech manufacturing, it still lacks the depth of highly trained engineers and production managers found in Foxconn’s Chinese hubs.

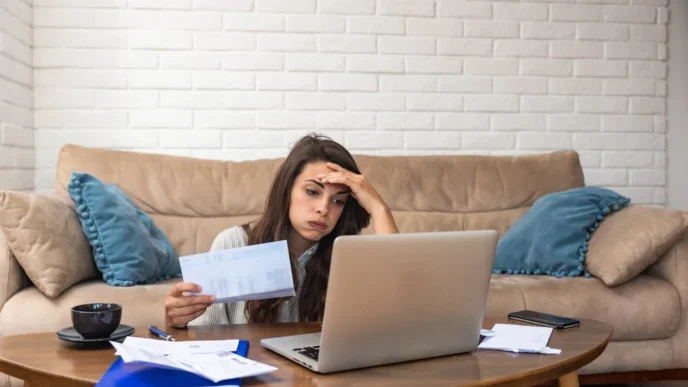

Analysts warn that these labor constraints may delay Apple’s ability to meet international demand from India, potentially affecting product availability during peak sales periods, such as the holiday season.

Operational Challenges Beyond Labor

Apple’s push into India is not just a staffing challenge:

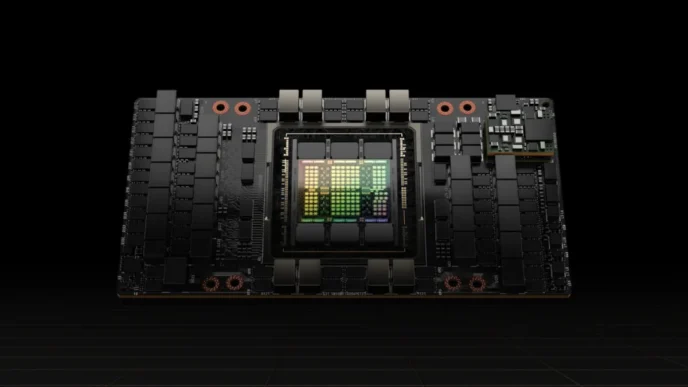

- Supply chain limitations: Many of Apple’s component suppliers are still concentrated in China. Even with assembly in India, key parts like chips, cameras, and display panels continue to travel from Chinese factories.

- Quality and scale: Maintaining Apple’s high-quality standards requires highly trained personnel. Foxconn’s reliance on experienced Chinese staff underscores the difficulties of replicating China’s production efficiency in India.

- Infrastructure hurdles: Indian manufacturing hubs, though improving, still face electricity constraints, logistics bottlenecks, and regulatory hurdles that can complicate large-scale electronics assembly.

Geopolitical and Economic Pressures

Apple’s diversification strategy is also shaped by geopolitical tensions and trade dynamics. Rising U.S.-China friction, including export restrictions on semiconductors and national security concerns, has accelerated Apple’s India expansion. The recall of staff to China, however, highlights the delicate balancing act: Apple must maintain production in China to serve its massive domestic market while simultaneously scaling operations abroad to reduce geopolitical exposure.

India’s Role in Apple’s Future

Despite these hurdles, India remains a strategic priority for Apple. The company has secured significant incentives under India’s Production-Linked Incentive (PLI) program, which encourages electronics manufacturing and aims to boost local job creation. By gradually increasing assembly capacity in India, Apple hopes to:

- Reduce reliance on China for production.

- Cater to regional demand in Asia and Europe.

- Position itself favorably with governments encouraging domestic manufacturing.

Foxconn’s ability to transfer skills, train local staff, and maintain quality standards will be critical to achieving these objectives.

Market and Investor Reactions

Investors are closely monitoring the situation. While some see short-term delays in India as a minor setback, others caution that sustained reliance on Chinese labor could undermine Apple’s broader risk diversification strategy. Market analysts note that any disruption in India could affect product launches and supply timelines, potentially impacting sales and stock performance.

At the same time, Apple’s continued commitment to India signals confidence in the country’s long-term potential as a global manufacturing hub.

Conclusion

Foxconn’s recall of Chinese staff to Chinese factories is a reminder of the complex realities behind Apple’s ambitious India expansion. While the company is moving steadily toward diversifying its supply chain, skilled labor, infrastructure, and component sourcing remain significant constraints.

Apple’s ability to replicate the efficiency, quality, and scale of its Chinese operations in India will determine how successfully it can reduce reliance on China without compromising its global market leadership.